The industry of plastics has vastly expanded and developed in recent years. Rotational molding is a special and well-liked way of developing plastic-type material merchandise which has been rising in popularity throughout the years. Rotomolding is a production method that makes use of temperature and rotation to produce hollow plastic-type material pieces. Rotational molding enables the roll-out of Rotomolding products that might be extremely hard to produce utilizing other developing methods. With this blog post, we will acquire a good look at the skill of creating plastic material products through rotomolding.

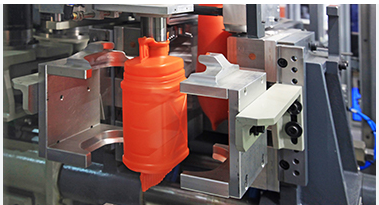

The process of rotomolding starts with the pouring of plastic-type resin in a mildew. The mold will then be heated up and rotated in several guidelines to make certain an even warmth syndication. The plastic-type material inside the mold melts and flows in the preferred model of the product, generating a hollow aspect. As soon as the plastic-type material has cooled and solidified, the product is taken away in the mold and it is prepared for concluding touches.

A benefit of rotomolding is that it can develop intricate and elaborate forms with comparable relieve. Rotational molding is fantastic for developing parts with consistent wall surface thicknesses, and that is a essential element in making sure that the product maintains its structural integrity. Each step within the developing process is closely observed to ensure good quality and accuracy and reliability within the ultimate product or service.

All the different items created through rotational molding is considerable. Rotomolding produces elements that cover anything from small auto elements to large safe-keeping tanks, playground equipment, and in many cases kayaks. The flexibility of rotational molding, coupled with its ability to develop parts with various shapes and sizes, makes it an attractive choice in the developing market.

Another advantage of rotomolding is being able to produce goods with multi-layer building. This approach will allow rotomolders to produce things with unique films, more durability, and also other attributes the merchandise might require. Multi-layering also makes it possible for goods to be designed to distinct demands, including those essential for harmful components.

Rotomolding is undoubtedly an eco-warm and friendly producing approach. The plastic material resins utilized at the same time are 100% recyclable, creating rotational molding an environmentally friendly procedure for production. This feel puts the product in line with the round economic system viewpoint.

In a nutshell:

In In a nutshell, rotational molding is definitely an revolutionary, inexpensive, and eco-warm and friendly producing process that has taken the plastic merchandise market by hurricane. This method’s flexibility will allow suppliers to generate plastic material merchandise with diverse designs, styles, and walls thicknesses that satisfy the certain requirements of their buyers. Rotational molding could also be used to generate items with multi-layered design, offering consumers with impressive and designed remedies. Using the growing pattern towards eco-pleasant procedures and sustainability, rotomolding will certainly be around for several years into the future.